Exploring the CrysPack Wafer Box: Enhancing Semiconductor Shipping

2024.06.17 / By hqt

In the fast-paced world of semiconductor manufacturing, the transportation and handling of delicate wafers pose significant challenges. One of the critical components in this process is the wafer box, specifically designed to protect these thin and sensitive devices during shipping and handling. CrysPack, a renowned manufacturer in this niche, offers innovative solutions to mitigate common issues such as die migration, ensuring that the integrity and yield of these wafers remain intact from production to deployment.

Understanding the Challenges of Thin Die Transportation

Issues with Traditional 4” Waffle Packs

Shipping today’s ultra-thin semiconductor wafers, often less than 250µm thick, requires meticulous attention to packaging. The industry standard 4” waffle packs, or chip trays, are commonly used for this purpose. However, these trays present challenges, particularly regarding the migration of thin dies out of their designated pockets during transit. This phenomenon not only increases the likelihood of damage but also escalates costs due to rework labor and yield loss.

The Role of CrysPack’s Innovative Solutions

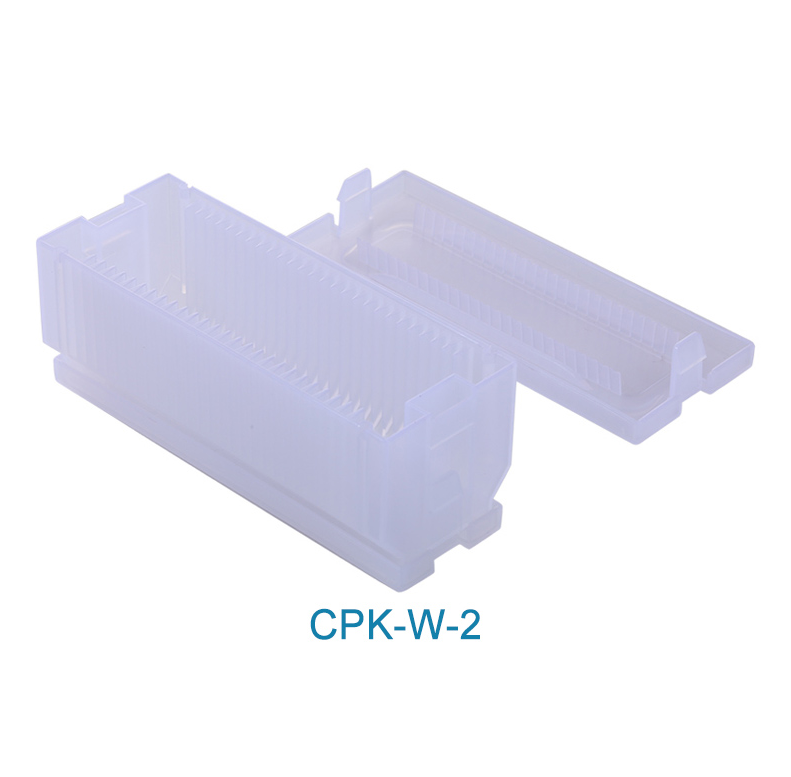

CrysPack addresses these challenges head-on with its advanced wafer box solutions. Specifically, their Wafer Box CPK-W-2 lid for the 4” waffle packs is engineered to prevent thin dies from migrating out of their pockets. This lid incorporates sophisticated technology derived from the patented LCS2 lid, ensuring a secure fit that tightly compresses the tray and lid together. This compression is crucial as it eliminates gaps that could otherwise enable die migration, thus safeguarding the wafers throughout their journey.

Features and Benefits of CrysPack’s LS4 Lid

Design and Functionality

CrysPack’s Wafer Box LS4 lid offers several key features designed to enhance the safety and reliability of wafer transportation:

Uniform Sealing: The LS4 lid uniformly seals each individual tray pocket, preventing any movement of the wafers within.

Warpage Compensation: It compensates for common warpage conditions in waffle pack lids and trays, effectively eliminating gaps that could lead to die migration.

Cost Savings: By preventing die migration, the LS4 lid significantly reduces costs associated with yield loss, rework labor, and RMAs (Return Merchandise Authorizations).

Advanced Materials

The LS4 lid integrates anti-static Tyvek interleaf material, which plays a dual role: it eliminates the need for manual placement of Tyvek paper during loading and ensures static dissipative properties with a silicone-free design. This feature is critical in semiconductor environments where electrostatic discharge (ESD) can pose serious risks to sensitive electronic components.

Understanding CrysPack: A Leader in Wafer Box Manufacturing

Introduction to CrysPack

CrysPack is a renowned manufacturer specializing in the production of high-quality wafer boxes and VR Plates. With a commitment to innovation and reliability, CrysPack offers a range of products designed to meet the diverse needs of the semiconductor industry.

Technology Behind CrysPack Wafer Boxes

CrysPack employs CrysPack Vacuum Release® Technology in their VR Plates, ensuring secure immobilization of wafers without direct contact. This technology minimizes the risk of damage during handling and transport, particularly beneficial for fragile substrates like InP wafers, GaAs wafers, and MEMs wafers.

Customization Options

CrysPack provides customization options to tailor VR Plates according to specific requirements. This flexibility includes custom sizes, different Gel retention levels (XT, XL, X4, and special orders like X8), and various mesh sizes (standard 16 mesh or 33 mesh upon request).

Materials and Configurations

VR Plates from CrysPack are manufactured using specialized Process B Gel material, ensuring optimal protection and support for wafers. These plates are available in brown phenolic (C) or transparent acrylic (T) materials, catering to different storage and handling needs.

Features and Benefits of CrysPack Wafer Boxes

Enhanced Protection for Wafers

The CrysPack Vacuum Release® Technology used by CrysPack enhances the protection of wafers by securely immobilizing them without direct contact. This feature is particularly beneficial for diced wafers on film frames, preventing potential edge damage during transport.

Versatility in Application

CrysPack wafer boxes are versatile and can accommodate a wide range of wafer sizes from 75mm to 450mm. They are suitable for various substrates, including thin and fragile materials, where maintaining structural integrity is critical.

Storage Solutions

In addition to VR Plates, CrysPack offers outer container boxes designed for storage and additional protection. These boxes are available in conductive black (C) or transparent (T) materials, providing options based on specific environmental and storage requirements.

Customization Options and Technical Specifications

Tailored VR Plate Designs

CrysPack’s ability to create custom VR plate sizes allows semiconductor manufacturers to optimize storage and handling processes according to specific needs. Whether it’s accommodating larger wafers or ensuring compatibility with unique handling equipment, custom designs provide flexibility and efficiency.

Gel Retention Levels

The availability of different Gel retention levels (XT, XL, X4, and special order X8) ensures that CrysPack wafer boxes can support various device sizes, weights, and surface roughness. This customization is crucial for maintaining secure positioning and protection during transportation.

Material Choices

The choice between brown phenolic (C) and transparent acrylic (T) materials for VR Plates and storage boxes allows users to select based on visibility needs and environmental considerations. Transparent options facilitate visual inspection, while conductive materials mitigate ESD risks.

Technical Specifications and Application Scenarios

Static Dissipative Properties

The LS4 lid boasts a static resistance of less than E9 ohms, meeting stringent industry standards for static dissipative materials. This ensures that static charges are safely dissipated, preventing any potential damage to the wafers due to electrostatic discharge during handling and transportation.

Compatibility and Integration

Designed to work seamlessly with CrysPack’s standard 4” clip, the LS4 lid not only enhances the security of wafers within the waffle packs but also simplifies the packaging process. Its padded construction provides additional cushioning, further protecting the wafers from physical shocks and vibrations during transit.

Environmental Considerations

In addition to its functional benefits, the LS4 lid is environmentally conscious with its silicone-free design. This reduces the environmental footprint of semiconductor packaging processes, aligning with global sustainability initiatives increasingly prioritized across industries.

Use Cases and Industry Applications

Semiconductor Manufacturing

For semiconductor manufacturers, ensuring the integrity of wafers is paramount. The LS4 lid by CrysPack finds extensive use in facilities where high-volume production and shipment of delicate semiconductor devices occur. Its ability to prevent die migration and minimize handling-related damages makes it an indispensable tool in maintaining high yield rates and reducing operational costs.

Research and Development

In R&D environments, where innovation and experimentation with new semiconductor technologies are constant, the LS4 lid supports the safe transport of prototype wafers. Its reliability in preventing die migration ensures that valuable research materials reach their destinations intact, facilitating uninterrupted progress in technological advancements.

Quality Assurance and Compliance

Meeting rigorous quality standards is non-negotiable in the semiconductor industry. The LS4 lid not only meets but exceeds these standards, providing peace of mind to manufacturers regarding the safety and reliability of their shipments. Its compliance with industry regulations underscores CrysPack’s commitment to delivering products that uphold the highest levels of quality assurance.

Conclusion: The Future of Semiconductor Packaging

CrysPack’s Wafer Box LS4 lid represents a significant advancement in semiconductor packaging technology, specifically tailored to address the challenges posed by thin die migration in 4” waffle packs. By integrating innovative design features with advanced materials, CrysPack continues to set the benchmark for reliability and performance in wafer transportation solutions. As semiconductor technologies evolve, so too will the need for robust packaging solutions like the LS4 lid, ensuring that the promise of high-performance computing and electronics remains securely protected through every stage of production and distribution.