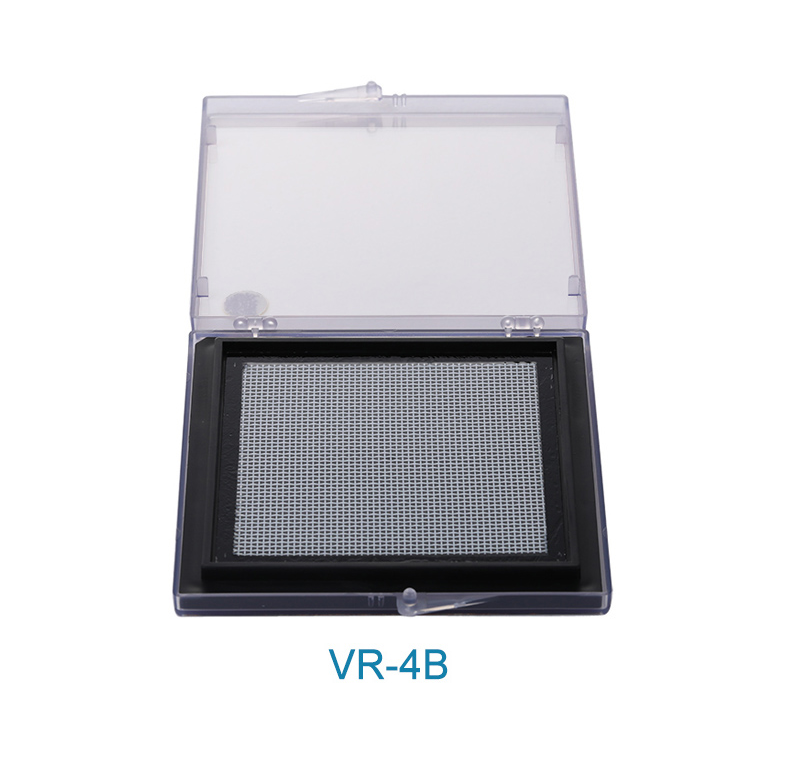

Vacuum Release Tray Clips: Perfect Solution for Delicate Components

2024.09.20 / By hqt

When it comes to handling delicate optical, semiconductor, and medical components, the challenge is always the same: how can you ensure these fragile items arrive undamaged? Whether you’re dealing with thin, fragile semiconductors or sensitive optical instruments, any mishandling during transport can lead to costly breakages. This is where vacuum release tray clips come into play, offering a robust and efficient solution. But what makes these clips the go-to choice for industries such as telecommunications, optoelectronics, and medical device manufacturing? Let’s explore the innovation behind vacuum release tray clips, developed by Fuzhou Cryspack Opto-Electronic Technology Co., Ltd., and how they’re reshaping the way delicate components are packaged and transported.

What Are Vacuum Release Tray Clips?

The Innovation from CrysPack

Vacuum release tray clips are an innovative packaging solution, developed by Fuzhou Cryspack Opto-Electronic Technology Co., Ltd., designed specifically to safeguard extremely fragile or thin devices during transportation. These clips are widely utilized in industries like semiconductors, optoelectronics, and telecommunications. The brilliance of this packaging lies in its vacuum sealing technology, which provides a solid, secure environment free of oxygen and moisture. By eliminating these elements, the vacuum clips protect sensitive components from corrosion and other environmental damage.

The development of vacuum release tray clips offers a significant step forward in the packaging of delicate components, minimizing the risk of scratches or contact damage during transit. Whether it’s a fragile semiconductor chip or a delicate optical component, these clips serve as a vital safeguard, ensuring products reach their destination safely.

Key Features of Vacuum Release Tray Clips

The vacuum release tray clips come equipped with several features that make them indispensable for handling sensitive components:

Vacuum Sealing Technology: This feature creates a controlled, oxygen-free environment that minimizes the risk of contamination, corrosion, or moisture damage, making it especially suitable for optical and semiconductor components.

Customizable Dimensions: Available in a wide range of sizes, these tray clips can be tailored to fit almost any optic or semiconductor device, enhancing their versatility across different industries.

Durable and Impact-Resistant Material: Made from high-strength plastic, these clips are not only impact-resistant but also durable enough to ensure long-lasting performance. This makes them ideal for repeated use during the handling and shipping of components.

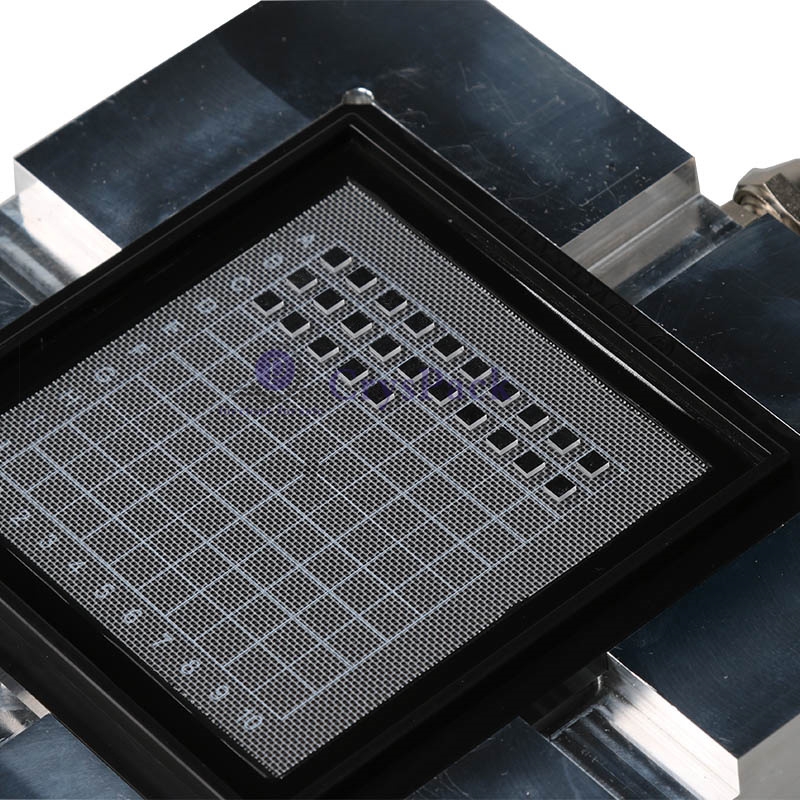

Non-Contact Protection: Unlike traditional packaging methods where components might touch surfaces, vacuum release tray clips suspend the optics or devices within a vacuum, ensuring minimal contact and reducing the risk of mechanical damage.

Customizable Retention Levels: Whether you’re dealing with lightweight optical devices or heavier semiconductor components, the clips can be customized to offer various retention levels, ensuring secure and flexible packaging.

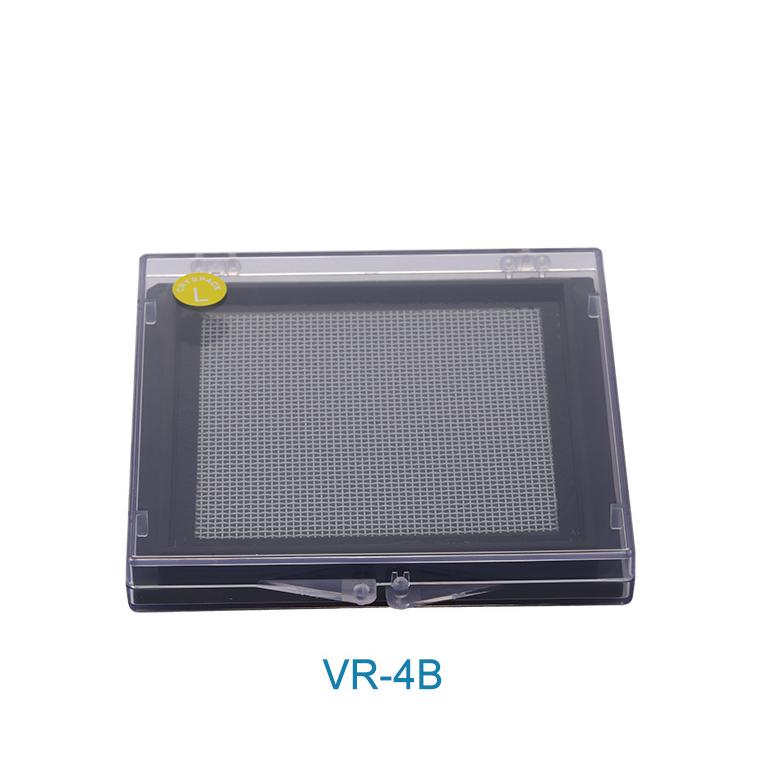

Clear Visibility: With a transparent lid, managing inventory becomes much easier. You can visually inspect the contents without opening the package, ensuring that the correct components are in place.

Applications of Vacuum Release Tray Clips

Semiconductor Packaging

In the semiconductor industry, handling and transporting delicate chips and wafers is critical. Even the slightest scratch can render these components useless. Vacuum release tray clips solve this issue by providing non-contact protection during transport. The vacuum-sealed environment also shields the semiconductors from static electricity, dust, and other contaminants, ensuring that they arrive intact and ready for use.

Optical Storage and Packaging

Optical components, such as lenses or sensors used in high-end instruments, require the highest level of care during handling. Vacuum release tray clips offer a non-contact suspension system, allowing these sensitive components to be packaged without any risk of abrasion or scratches. The vacuum environment keeps out moisture and dust, which are particularly detrimental to optical devices.

Optoelectronics Packaging

Optoelectronic devices, which combine optical and electronic functions, are notoriously fragile. Components such as LEDs, sensors, and fiber optics require careful handling to prevent damage. Vacuum release tray clips provide the necessary protection by reducing physical contact and offering customizable retention levels to fit each component precisely, ensuring no shifting or movement during transport.

Telecommunication Equipment Packaging

The telecommunications industry relies on fragile optical components, like fiber optics, that need to be packaged with care. Vacuum release tray clips help protect these components during transportation and installation, ensuring that the delicate optical fibers remain undamaged.

Medical Device Packaging

Many medical devices rely on optical components, such as endoscopes or imaging devices. During storage and transport, these components are susceptible to contamination or physical damage. Vacuum release tray clips not only provide a clean, sealed environment but also keep the components secure and free from impact damage.

The Advantages of Vacuum Release Tray Clips

Superior Product Protection

One of the biggest advantages of vacuum release tray clips is their superior protection. The vacuum-sealed environment keeps out moisture, dust, and other contaminants, while the non-contact protection system ensures that delicate components are not damaged by physical impact. This makes vacuum release tray clips one of the safest ways to transport sensitive components, whether in the semiconductor, optical, or medical fields.

Time-Saving and Efficient

By providing quick and easy loading and unloading processes, vacuum release tray clips streamline handling operations, saving both time and labor costs. This efficiency is especially crucial in high-volume manufacturing environments where delays can lead to significant losses. Additionally, the transparent lid allows for quick inventory checks without disrupting the packaging.

Versatility Across Industries

The versatility of vacuum release tray clips makes them applicable across many industries. Whether you’re working in semiconductor manufacturing, optoelectronics, telecommunications, or medical devices, these clips provide the right solution for packaging fragile components.

Cost-Effective Solution

Although vacuum release tray clips provide high-end protection, they are also cost-effective. Their durable, reusable materials reduce the need for replacement, and the protection they offer reduces damage-related returns. The overall reduction in product loss and increased efficiency leads to cost savings across the board.

Vacuum Release Tray Clip Configurations

Vacuum release tray clips come in various sizes and configurations, allowing for maximum flexibility depending on the application:

Tray Sizes: Available in 2-inch, 4-inch, 5-inch, and 6-inch sizes based on JEDEC standards, making them compatible with industry-standard trays.

Retention Levels: To accommodate components of different sizes and weights, retention levels come in a wide range: XL, L, M, H, and HH, ensuring that even the most delicate or heavy components remain secure.

Mesh Geometries: With customizable mesh geometries (16, 33, 76, 103, 137, and 195), these clips can be tailored to support components with varying requirements.

Custom Print Patterns: Companies can also customize the print patterns on the trays, adding branding or component identification directly on the packaging, which aids in better inventory management and presentation.

Conclusion: Why Vacuum Release Tray Clips Are Essential

Vacuum release tray clips, developed by Fuzhou Cryspack Opto-Electronic Technology Co., Ltd., offer an innovative solution to a common problem across several industries: how to transport fragile, delicate components without damaging them. With features like vacuum sealing technology, non-contact protection, and customizable retention levels, these clips provide a level of safety and efficiency that’s hard to beat.

Whether you’re handling semiconductors, optoelectronic devices, or medical optics, vacuum release tray clips provide the ultimate packaging solution. Their versatility, cost-effectiveness, and superior protection make them an essential part of modern industrial packaging.