Enhance device handling efficiency with Vacuum Boxes from CrysPack. Explore the impact of mesh size on device unload performance, guidelines for optimal mesh geometry selection, and clarifications on mesh size’s role in Vacuum Release technology. Optimize unloading processes, prevent mis-pick issues, and streamline device handling with informed decisions based on expert recommendations.

Introduction to Vacuum Boxes

1.1 Overview of Vacuum Release™ (VR Series) Tray Technology

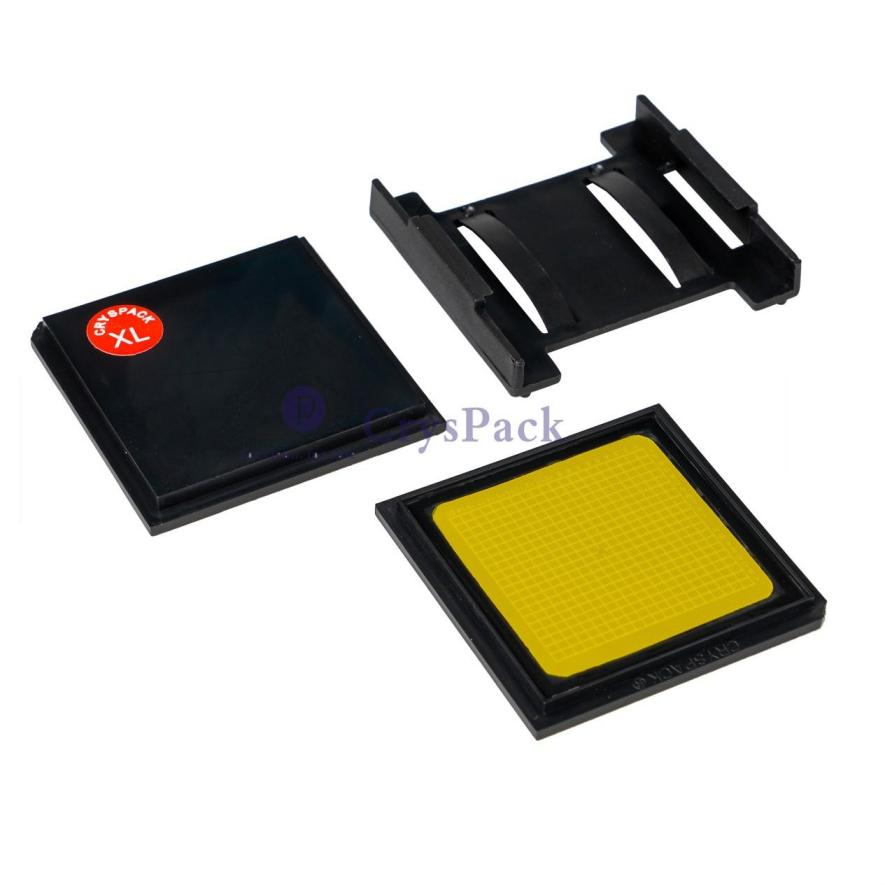

Vacuum Boxes, pioneered by CrysPack, revolutionize the way devices are securely transported and unloaded. The VR Series Tray technology combines innovation and functionality to ensure the safe handling of sensitive devices. These boxes utilize advanced Vacuum Release technology, setting them apart from traditional packaging solutions.

1.2 Securing Devices During Shipping and Handling

CrysPack’s Vacuum Boxes are engineered to securely hold devices during the rigors of shipping and handling. The unique design of the VR Series Tray, coupled with its elastic Gel membrane and mesh material, provides unparalleled protection. This ensures that devices remain intact and undamaged throughout the transportation process.

1.3 On-Demand Unloading with Vacuum Release Technology

One of the key features of Vacuum Boxes is their ability to release devices on demand for unloading. This innovative technology allows for precise control over when and how devices are removed from the packaging. By leveraging Vacuum Release technology, CrysPack ensures efficient and hassle-free unloading processes.

Understanding Vacuum Release Technology

2.1 Exploring Vacuum Release Mechanism

At the heart of Vacuum Boxes lies Vacuum Release technology, a sophisticated mechanism designed to optimize device handling. This technology relies on temporarily altering the surface contact area between the device and the VR tray. By strategically manipulating this contact area, Vacuum Release technology enables seamless unloading of devices when needed.

2.2 Impact of Surface Contact Area on Holding Force

The holding force exerted by Vacuum Boxes is directly influenced by the surface contact area between the device and the VR tray. As the surface contact area changes, so does the magnitude of the holding force. Understanding this relationship is crucial for ensuring the safe and secure transportation of devices.

2.3 Components of Vacuum Boxes

The effectiveness of Vacuum Release technology is further enhanced by the elastic Gel membrane and mesh material used in VR trays. These components work in tandem to provide optimal support and protection for devices. The Gel membrane ensures a secure grip on the devices, while the mesh material facilitates controlled release during unloading.

Optimizing Mesh Geometry for Device Unloading

3.1 Significance of Mesh Geometry in Unloading Performance

Mesh geometry, specifically Mesh Size, plays a critical role in the performance of Vacuum Boxes during device unloading. The size of the mesh directly impacts the number of contact points between the device and the VR tray. This, in turn, influences the efficiency and effectiveness of the unloading process.

3.2 Balancing Contact Points and Device Support

When selecting the appropriate mesh geometry, it is essential to strike a balance between minimizing contact points and ensuring adequate support for the device. Too few contact points may result in instability during unloading, while too many can impede the release process. By understanding the mesh geometry guidelines, users can optimize device unloading performance.

3.3 Guidelines for Mesh Geometry Selection

CrysPack provides comprehensive guidelines for selecting the optimal mesh geometry based on device dimensions. By referencing Figure 3 and Table 1, users can easily determine the recommended mesh size for their specific devices. These guidelines streamline the process of configuring Vacuum Boxes for maximum efficiency.

Impact of Mesh Size on Device Unload Performance

4.1 Influence of Mesh Size on Unloading Efficiency

Mesh size is a critical factor that significantly influences the performance of Vacuum Boxes during device unloading. The size of the mesh directly affects the number of contact points between the device and the VR tray, consequently impacting the ease and effectiveness of the unloading process. Understanding the relationship between mesh size and device unload performance is essential for optimizing the functionality of Vacuum Boxes.

4.2 Comparing Different Mesh Sizes

Different mesh sizes yield varying effects on contact points and, consequently, device unload performance. For instance, a larger mesh size with more significant spacing between thread lines results in fewer contact points when the VR tray is in release mode. On the other hand, a smaller mesh size with tighter spacing leads to a higher number of contact points. This comparison underscores the importance of selecting the appropriate mesh size based on specific device dimensions and unloading requirements.

4.3 Illustrating Mesh Size Impact

Visualizing the impact of mesh size through examples and diagrams enhances understanding. Imagine two scenarios: one with a large mesh size and another with a small mesh size. In the former, the device rests on fewer contact points, facilitating smoother unloading. In contrast, the latter scenario presents challenges as the device interacts with numerous contact points, potentially hindering the unloading process. Illustrative diagrams further elucidate how mesh size directly influences device unload performance.

Mesh Size Selection Guidelines

5.1 Guidelines for Optimal Mesh Geometry Selection

Selecting the optimal mesh geometry is paramount for ensuring efficient device unloading. CrysPack provides detailed guidelines tailored to different device sizes. By referencing these guidelines, users can determine the most suitable mesh size that strikes a balance between minimizing contact points and providing adequate support for the device during unloading. This strategic selection process optimizes device handling and mitigates the risk of damage or mis-pick issues.

5.2 Balancing Contact Points and Device Support

Achieving the right balance between minimizing contact points and ensuring device support is crucial for seamless unloading. Insufficient mesh contact points may result in device tilting when vacuum is applied to the tray, potentially leading to mis-pick issues. Conversely, an excessive number of contact points can exert unnecessary pressure on the device, compromising its integrity. By adhering to mesh size selection guidelines, users can mitigate these challenges and enhance unloading efficiency.

5.3 Addressing Mis-Pick Issues

Mis-pick issues, stemming from inadequate mesh contact points, pose a significant concern during device unloading. To prevent such occurrences, it is imperative to select a mesh size that provides sufficient support for the device. By following mesh size selection guidelines and ensuring the appropriate number of contact points, users can minimize the risk of mis-picks and optimize the unloading process. This proactive approach enhances overall efficiency and reliability.

Clarifying Mesh Size’s Role in Vacuum Boxes

6.1 Dispelling Common Misconceptions

There are often misconceptions regarding the role of mesh size in Vacuum Boxes. Contrary to popular belief, mesh size primarily affects device unload performance, not holding force during shipping. Understanding this distinction is essential for accurately assessing the functionality of Vacuum Boxes and optimizing their performance based on specific requirements.

6.2 Emphasizing Mesh Size’s Impact on Unload Performance

Mesh size directly influences device unload performance by determining the number of contact points between the device and the VR tray. It is crucial to recognize that mesh size plays a pivotal role in facilitating smooth and efficient unloading processes. By clarifying this relationship, users can make informed decisions when selecting mesh geometries and effectively leverage vacuum release technology to enhance device handling capabilities.

Conclusion

In conclusion, Vacuum Boxes represent a significant advancement in packaging technology, offering unparalleled security and convenience for device transportation and unloading. By leveraging Vacuum Release technology and optimizing mesh geometry, CrysPack ensures the safe and efficient handling of devices throughout their journey.

Post time: Apr-19-2024

Chinese

Chinese