In the realm of delicate electronics and semiconductor industries, the handling and transportation of fragile components pose significant challenges. Recognizing this, CrysPack, a renowned manufacturer in the field of semiconductor packaging solutions, has introduced an innovative solution – the Vacuum Release Tray. This breakthrough product is designed to securely hold fragile devices, including bare die, during shipping, handling, and processing, thus addressing the critical need for reliable protection and efficient handling in high-volume pick-and-place applications.

Understanding the Technology Behind the Vacuum Release Tray

1. Proprietary Gel and Vertec™ Film Membrane

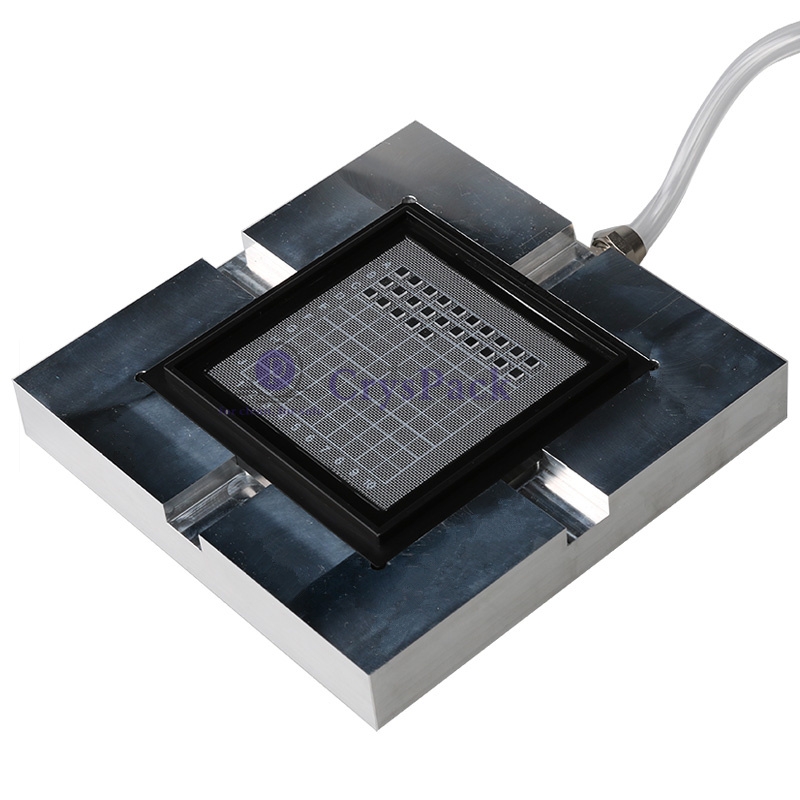

At the heart of the Vacuum Release Tray lies a sophisticated technology that combines a proprietary Gel or non-silicone Vertec™ film membrane with a mesh material. This unique combination enables the tray to securely hold components in place until they are released by applying a vacuum to the underside of the tray. This mechanism ensures that delicate devices remain intact and protected throughout the handling process, minimizing the risk of damage or breakage.

2. Enhanced Protection for Fragile Devices

The surface of the Vacuum Release Tray offers unparalleled protection for extremely fragile or thin devices, including bare die. By utilizing a Gel or Vertec™ film membrane, the tray ensures that there is no contact with the edges or the top surface of the device, reducing the risk of damage caused by friction or pressure.

3. Versatile Handling Capabilities

The versatility of the Vacuum Release Tray is evident in its ability to handle a wide range of device sizes, ranging from less than 250 microns to 75mm in both X and Y dimensions. This flexibility makes it ideal for a variety of applications, from small-scale delicate components to larger devices used in high-volume automated pick-and-place operations.

4. Customizable Configurations

To cater to diverse requirements, the Vacuum Release Tray is available in a range of configurations, offering different tack levels and tray sizes based on JEDEC standards. Additionally, customers can choose between Gel or Vertec™ film membranes, depending on their specific needs. The trays are also available in various colors and can be customized with prints or grids, further enhancing their suitability for different applications.

Applications of the Vacuum Release Tray

1. Protecting Fragile Components

The Vacuum Release Tray finds extensive use in industries where the protection of fragile components is paramount. Its ability to securely hold delicate devices, such as bare die, ensures that they remain intact during shipping, handling, and processing, minimizing the risk of costly damage or defects.

2. High-Volume Pick and Place Operations

In high-volume automated pick-and-place operations, efficiency and reliability are of utmost importance. The Vacuum Release Tray’s ability to securely hold components while allowing for easy release via vacuum makes it an invaluable tool in streamlining these operations, reducing downtime, and improving overall productivity.

3. Specialized Handling Requirements

For devices smaller than 250 microns, the NDT Tray is recommended, while for devices larger than 75mm, the Wafer/Large Format VR Plates offer the ideal solution. These specialized trays cater to specific handling requirements, ensuring optimal protection and efficiency for a wide range of device sizes.

Choosing the Right Vacuum Release Tray: A Guide by CrysPack

1. Mesh Size Matters

When it comes to selecting the perfect Vacuum Release Tray for delicate devices, one of the crucial factors to consider is the mesh size. The mesh size determines the efficiency of offloading performance, ensuring that devices are securely held in place while also allowing for easy release when needed. At CrysPack, the importance of mesh size customization is understood, which is why a wide range of mesh geometries, including 16, 33, 76, 103, 137, and 195, is offered. By matching the mesh size to the X and Y dimensions of the device, performance can be optimized, and maximum protection ensured during handling and transportation.

2. The Tack Level Dilemma

Another essential consideration when choosing a Vacuum Release Tray is the tack level of the Gel or Vertec film membrane used. The tack level determines the adhesion strength of the membrane, ranging from ultra-low to high. This versatility allows users to select the tack level that best suits specific application requirements, ensuring that devices are securely held in place without any risk of damage or residue. Whether gentle support for fragile components or strong adhesion for larger devices is needed, CrysPack offers a variety of tack levels to meet needs with precision and reliability.

Why Choose CrysPack?

CrysPack stands out as a trusted supplier of Vacuum Release Trays and other high-tech packaging solutions, thanks to its commitment to quality, innovation, and customer satisfaction. Since its founding in 2005, continuous efforts have been made to develop and produce various types of packaging for high-tech sophisticated products, catering to diverse industry needs. The extensive product range includes membrane boxes, sticky boxes, vacuum boxes, wafer containers, optic storage boxes, and more, each designed to provide optimal protection and convenience for delicate devices and components.

1. Specialized Solutions for Every Need

At CrysPack, it is understood that no two applications are the same, which is why a diverse range of packaging solutions is offered to meet the unique requirements of customers. Membrane boxes feature a thin, highly elastic transparent film mounted to the top and bottom halves of a symmetrical box, offering the perfect solution for devices or large objects with irregular shapes or non-flat contact surfaces. Meanwhile, sticky boxes utilize a plastic-hinged design with a special gel coating on the bottom, providing secure fixation for tiny devices during transportation.

2. Innovative Packaging Solutions

In addition to Vacuum Release Trays, CrysPack offers a range of innovative packaging solutions tailored to specific industry needs. Vacuum boxes provide an innovative method for packing extremely fragile or thin devices, ensuring maximum protection during handling and transportation. Meanwhile, wafer containers offer a specialized packaging solution for semiconductor wafers, maintaining their integrity and cleanliness throughout storage and transport.

3. Quality Assurance and Customer Satisfaction

At CrysPack, quality is the top priority, which is why all products are produced by ISO9001 certification standards and manufactured in clean room environments. Dedicated efforts are made to provide customers with reasonable prices, short production times, and satisfactory after-sales service, ensuring a seamless experience from product selection to delivery. With a global customer base spanning more than a thousand companies, including industry leaders such as Coherent, Limo, IPG, and CASTECH, customers can trust CrysPack to deliver packaging solutions that meet their highest expectations.

Conclusion

The Vacuum Release Tray from CrysPack represents a significant advancement in the field of fragile device handling. Its innovative technology, coupled with versatile configurations and customizable options, makes it a valuable asset for industries where the protection and efficient handling of delicate components are critical. With its ability to securely hold fragile devices during shipping, handling, and processing, the Vacuum Release Tray sets a new standard for reliability and performance in semiconductor packaging solutions.

Post time: Mar-04-2024

Chinese

Chinese